Save time & money in your diagnosis, test the injectors.

Compression, Fuel, Air and Ignition, are the fundamental elements needed for all internal combustion engines to operate. In petrol engines, ignition of the fuel/air mixture occurs due to the generation of a high tension spark, while diesels require heat generated by an increase in cylinder pressure and temperature.

When each is supplied in the correct quantity - and at the correct time - an engine will start, run and operate efficiently within its design parameters.

Commercial or passenger vehicle’s may be subjected to harsh or extreme operating conditions, it may use a fuel with dubious quality, or may not receive regular or adequate servicing. Any of these situations are a recipe for mechanical or electrical failure of the engine and its control systems.

When a workshop is presented with a customer complaint reporting symptoms of: excess fuel usage, low power, rough running, excess black or white smoke from the exhaust, cylinder misfire, diagnostic trouble codes involving either lean or rich fuel trims, or in the case of common rail diesel (CRD) vehicles – repeated DPF regeneration – there are some basic checks that need to be performed as a first step in the diagnostic process.

Is the engine compression ok? How much airflow is there through the combustion chamber? Is the spark on a petrol engine sufficient? Is the fuel volume and pressure correct and available at the rail?

But what then?...... Modern vehicles are equipped with a number of subsystems designed to maximise the engines efficiency by continuously adjusting valve timing, increasing the volumetric efficiency through forced induction, smoothing firing pulses through variable injection quantity, altering intake runner length to promote airspeed, and electronically controlling emission output through intake and exhaust system devices.

Could anyone of these systems cause the fault? Even the best technicians are time poor in today’s fast paced workshops, so correct diagnosis is paramount to an economic and effective repair.

When diagnosing modern GDI or CRDi engine performance issues, you will often get to the stage where the fuel injectors might be at fault. Using a scan tool access the stored fuel trims, or running (idling) injection quantity values can be an indicator that fuelling is an issue. Confirm there are no vacuum leaks (petrol engines), or charge air leaks (diesel) to help isolate the problem to the fuel injectors.

As all workshops know, fuel injectors are very expensive components – especially CRD (piezo and solenoid) types, so having the ability to easily test and confirm their condition before replacement - is a game changer for the workshop and diagnostic technician.

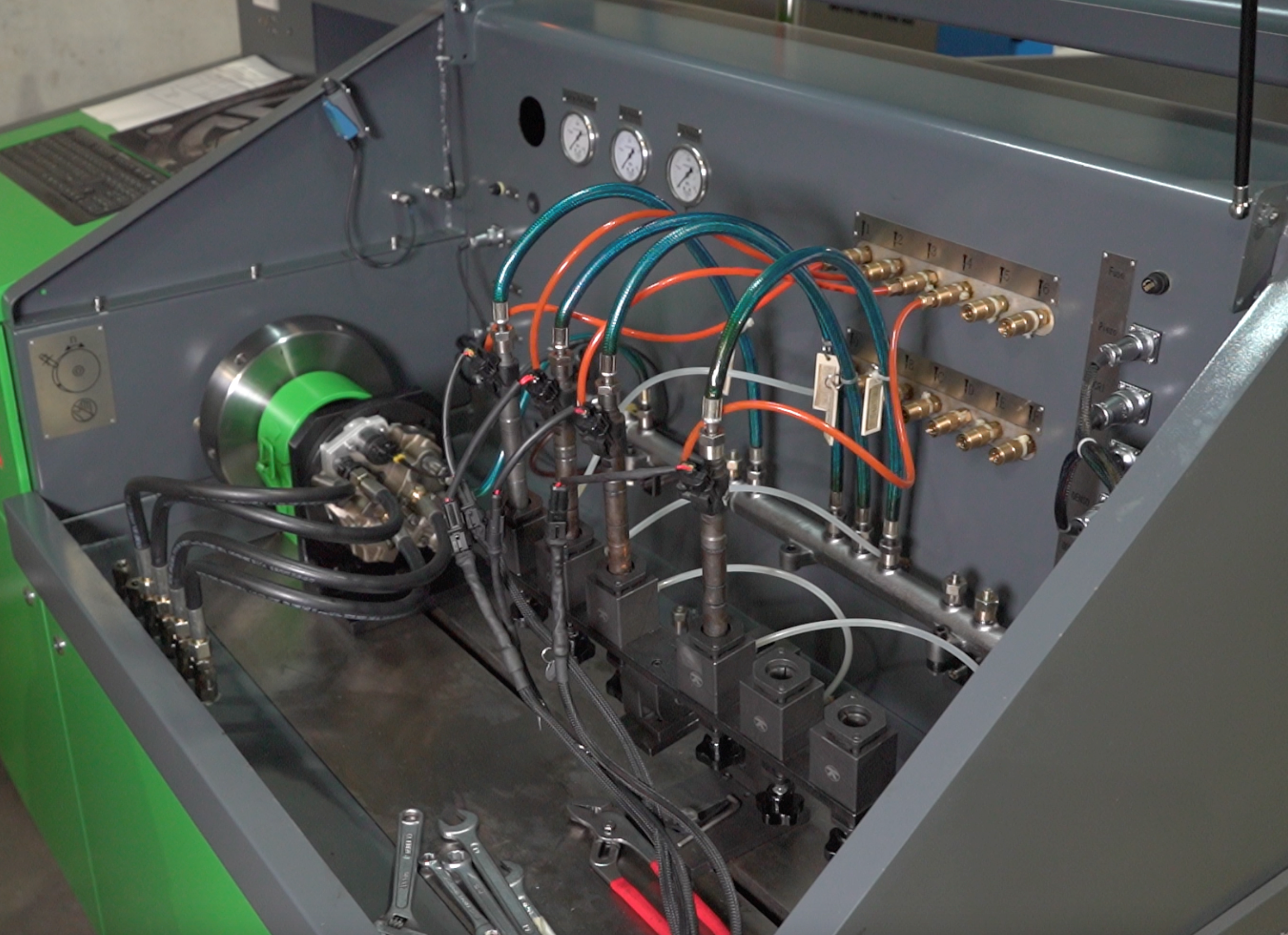

Using modern, dedicated testing equipment and a database of CRD and GDI injector specific information, the highly trained and experienced technicians at Injectronics can assist in the diagnostic process by accurately checking the operation of fuel injectors, and providing a specialised report on their condition.

This report indicates injector flow and fuel rates performed under several operating cycles:

- Full load,

- Emissions mode,

- Idle mode,

- Pre injection (CRDi)

- Leakage

Fuel injectors should always be tested as a matched set in any GDI and CRDI engine. This ensures accuracy during the diagnostic procedure. All fuel injectors are ultrasonically cleaned to ensure consistency and once reassembly is complete, they are capped, sealed, and shipped back to you.

If any fuel injectors are found to be problematic, Injectronics can offer replacement alternatives in their Goss or Genuine OEM brands